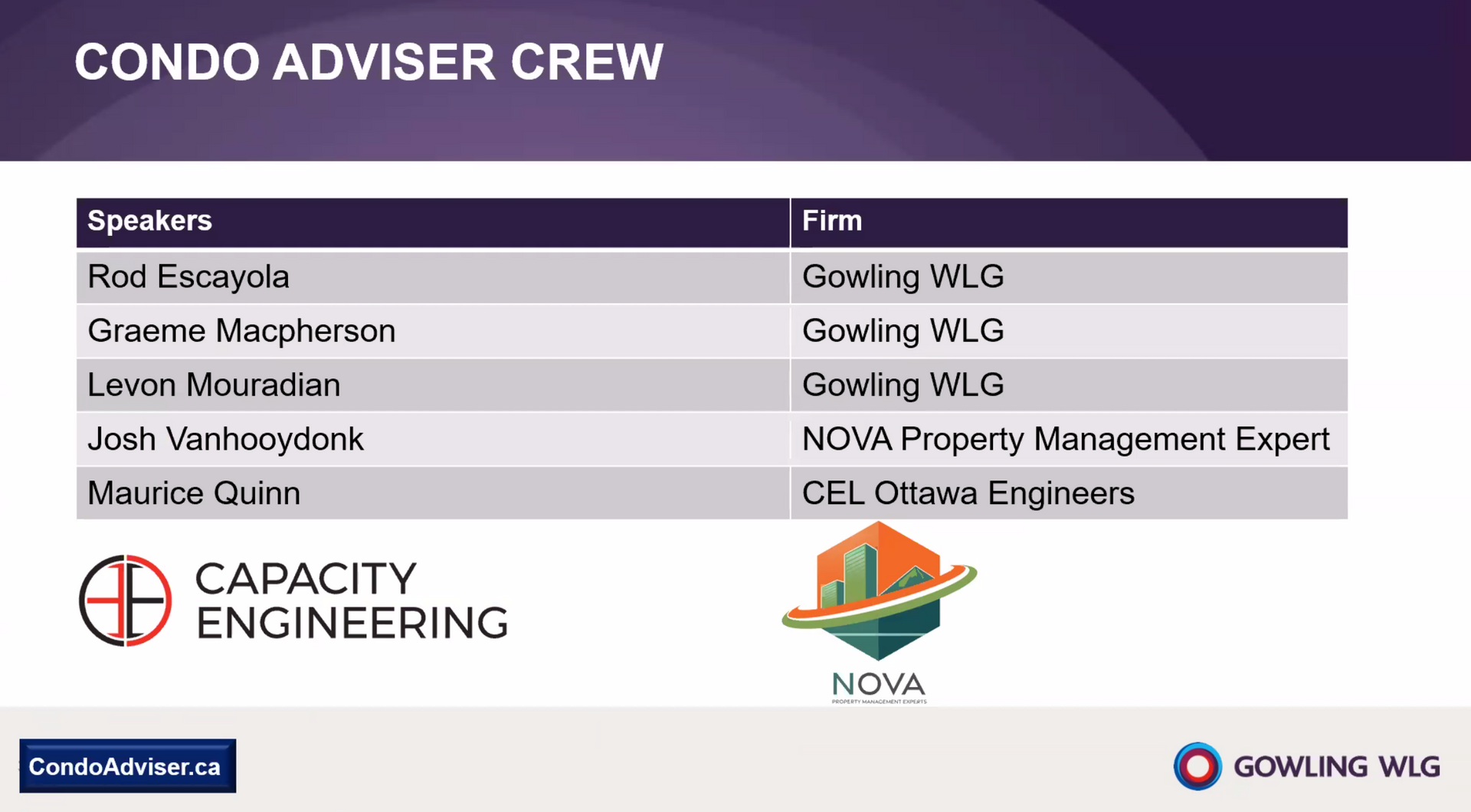

Cold Weather Concreting and Marginal Weather

To heat, or not to heat, that is the question...

In a temperate climate it is crucial to understand the impact of weather conditions on concrete operations, and this time of year we are seeing a transition to requiring Cold Weather Concrete Procedures. While concrete can be placed and finished in a broad range of temperatures, these operations must be undertaken with the correct precautions, and understanding of the chanllenges likely to be faced.

Recently we recommended that cold weather concreting procedures be undertaken; these were limited and straightforward. Pre-heating. Hot water Saturated Surface Dry condition. Hot water to prepare the mix. The work went off without a hitch, and so did the concrete.

Yesterday, the second pour was undertaken, and the weather appeared cooperative. The product in question requires 3 degrees, for a limited time period, and the Contractor proceeded without the cold weather adapted procedure. Today, the concrete was somewhere between initial and final set, nowhere near the 18MPa anticipated after 24hours with this product. A day's production lost, and a scramble to try and save the concrete. Heating has been provided, insulated tarps, and a hoarding added. Tomorrow we'll check again; in my honest opinion, cold water and cold work conditions are responsible for the problems. I don't foresee issues, but I thought an annonymous - potentially useful - open bet as to what is going to happen might be interesting and useful. Let's discuss in some high-level detail.

Cold weather poses unique challenges and risks that, if not properly managed, can lead to significant problems, including retarded inital and final set, delayed or reduced strength, increased permeability, and potential structural failure. In this blog post, we will explore the dangers of carrying out concrete operations in marginal weather, with a particular focus on cold weather concreting. Easy enough to know what to do in the dark of winter, but what about those days when you are looking good, and might just think about taking the risk? The marginal cases...

Before we go into any detail, let's define what we mean by "marginal weather." For the purposes of this discussion, we will consider marginal weather to be conditions that are close to, but not quite, beyond the recommended limits for concrete placement and curing. In the case of cold weather concreting, these limits typically begin at overnight temperatures of 7 degrees Celsius and lower, with many jobs going well down to zero thanks to the heat of hydration from the concrete. You also cannot be at or near zero in the forms or adjacent materials when placing if you hope to get through a zero degree overnight.

One of the primary dangers of cold weather concreting is the potential for reduced strength. Concrete gains strength through a chemical reaction between cement and water called hydration. This reaction is temperature-dependent, meaning that colder temperatures can significantly slow down the hydration process, resulting in lower ultimate strength. To mitigate this risk, it is essential to take measures to maintain the temperature of the concrete and its surroundings during placement, finishing, and curing. The concrete can be a source of heat, but not the only source, and not until the reactions are well underway. If the mix freezes before it can significantly react, you're cooked.

Another danger of cold weather concreting is increased permeability. Permeability refers to the ability of water to pass through concrete. In cold weather, the slow hydration process can result in a less dense and more porous microstructure, which can increase the permeability of the concrete. This increased permeability can lead to several problems, including corrosion of reinforcing steel, freeze-thaw damage, and reduced durability. A significant irony where microbubbles (air entrainment) is frequently purposefully added in order to provide freeze-thaw tolerance.

- To address these risks, it is essential to follow best practices for cold weather concreting. These practices include:

Preheating the materials: Heating the aggregates, cement, and mixing water can help maintain the temperature of the fresh concrete during placement, finishing, and curing. - Using insulated forms or enclosures: Insulating the forms or enclosures can help maintain the temperature of the concrete and its surroundings, promoting hydration and reducing the risk of freeze-thaw damage.

- Increasing the cement content: Increasing the cement content can help generate more heat during hydration, which can compensate for the slower hydration process in cold weather.

- Using accelerating admixtures: Accelerating admixtures can speed up the hydration process, helping to maintain the strength and durability of the concrete in cold weather.

- Protecting the concrete from freezing: Protecting the concrete from freezing during the first 24 hours after placement is critical for ensuring adequate strength gain and durability. Be careful to continue protection and heating through to the target strength, as well as well past the point that the mix is no longer at or near saturation. Free water in the mix is liable to freeze, and if there is too much water, there will be no space for ice crystals to form without risking the integrity of the concrete.

Ultimately, the success of a concrete pour has as much to do with knowing the conditions the concrete will face, and taking the appropriate precautions, as it does with the quality of concrete placed on site. Be careful, and protect yourself and your concrete out there.