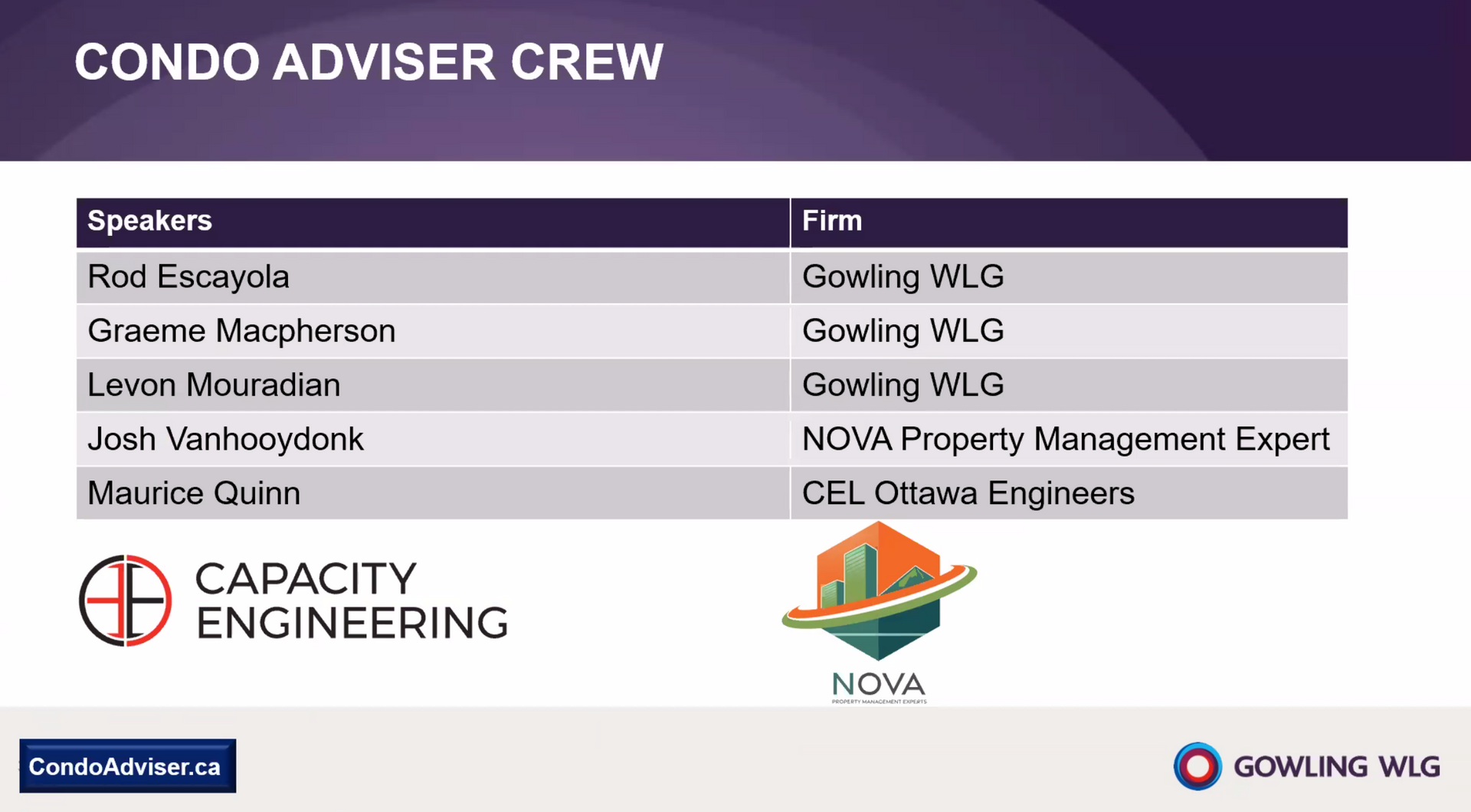

What's in a name? Terms and Code Language...

Understanding that words matter.

Words matter. We also see them everywhere. Do you read meaning into the image above? 'Scribe', perhaps...

It isn't there. That is a meaningless AI-generated picture produced to the prompt "Building Code word play and definitions." We read meaning into everything around us... There are numerous formations of how to represent the process of communication, however our firm normally models this as being a five step process (Concept, Encoding, Transmission, Decoding, Understanding). Every step inherently contains the potential for misunderstanding. What is understood from that was conceived does not necessarily bear much resemblance one to the other. So when it can go wrong even with the best of intentions, care, and caution, what happens when we are unable to agree on something as simple as a definition? Misunderstanding, and worse: Error. Sometimes even accusations of bias and professional negligence. Let's take a closer look.

Often in our work, we are required to interpret terminology and indeed to testify as to the specific meaning of words. Codes and Standards rely upon words, and they are not casually used nor interpreted. There are several types of words of signficant import in our work, and knowing them only comes with experience and time. Many engineers go through an entire career never learning the finite minutia of exacting terminology. Forensic Engineers have little choice but to be exacting, and as such our firm has made a point of understanding and training staff in the precise meaning of terminology.

Let's take a perplexing example: Standards may be withdrawn. A lay understanding of this might be that this would mean you should not rely upon, or use, such a standard. Nothing of the sort in our technical world; to be "withdrawn" as a Standard is to be enobled and taken out of the hum-drum world of revision and change. To be withdrawn in the case of a Standard is to be taken out of the cycle of updates and changes; to be enshrined as useful forever more, unaffected by the cycle of academic update whim.

In engineering, and specifically in code governed, standards driven professional work, there are often reserved terms which have specific definitions. Those words are defined as building blocks to our understanding. They are explicit and well understood; there is little debate as to meaning. Where we have defined terms, we can often reach to a reserved terms list for specific understanding. If you look at the governing code for our core jurisdiction (Ontario; Ontario Building Code [OBC]), as well as the national model code (National Building Code of Canada [NBCC]), reserved terms are italicised.

Recently, our firm had cause to get very specific with terminology surrounding snow fall and snow accumulation. It is interesting to note that a great deal of snow that falls never accumulates at all. Additionally, snow that falls may not remain in place due to melting and sublimation. What is the density of a snow on the ground? What depth of snow matters?

For every topic into which we have cause to begin a forensic review, the complications and details are almost immediately dynamic and far more labyrinthine than anyone would reasonably anticipate. Let's look at snow in forensic detail.

"Snow accumulation" is a technical, defined, term. It means snow that has fallen and remained on the ground. There is a formula for accumulated snow, being: Accumulation = Snowfall + Compaction + Drift + Melting + Sublimation

Codes and standards may make use of similar, but distinct, words. When they do so, we take it as given that there is a reason for such use. In our recent review of technical terminology surrounding snow, snow fall, snow depth, and snow loads, we concluded that there were two important, but entirely distinct, terms which needed to be understood.

Anticipated Snow Level: The depth of snow that may fall in a given predicted weather period, without regard for accumulation.

Accumulated Snow: The snow that will fall and be retained on the ground, including consideration of compaction, drifting, melting, and sublimation.

In addition to this, reviewing the literature showed that there is a significant difference in Anticipated Snow and Accumulated Snow with respect to density. Anticipated Snow, ie: fresh snow from a storm or event, has a density of between 0.5 kN/m3 and 1.0 kN/m3. Accumulated Snow is generally accepted as having a density of between 2.0 kN/m3 and 5.0 kN/m3.

Thus the literature treats these two types of snow very differently. While we may be required to maintain a separation above an anticipated snow level (ie: to permit space for snowfall from a single storm), code requirements may allow air intakes to align with the depth of expected snow accumulation. These requirements at first appear to be in conflict, but are easily understood when we pay close attention to the meaning of the words involved.

All code requirements are an effort to apply an economical solution to the majority of situations, most of the time. They are, in effect, a one-size-fits-most cookbook of pre-determined solutions. They will not cover every situation, but act as a legal minimum to define negligence. If a design meets code, but fails, that does not mean that the designer or builder, city or other party did anything wrong. Tossing a handful of pennies into the air may see some touching one another after they fall. Statistics are unforgiving, as is mother nature.

Additionally, having built a structure does not mean that it may be occupied and operated or used without maintenance. Ongoing maintenance is a presumption of every building code. Unoccupied, unheated, and unused buildings rapidly deteriorate, and durability of materials and assemblies is calculated, estimated, and designed based upon an occupied condition.

If you have a gas-fired appliance, keep your air intake and vent pipes free from snow, but also from vegetation, garbage, sheds, shelves, air conditioners, birds' nests, and anything else. They must be free and unobstructed; keeping them that way is not the responsibility of the builder, warranty corporation, or anyone other than the property owner.

Words matter. Maintenance matters. Biased? Mokusatsu.